Home made sex toys– It's never been easier

You are an adult now, the days of experimenting with household items or edibles are way behind you. The market for adult toys now offers a huge selection that can be overwhelming. But nothing can be more personal than a self-made item. Taking up one of our user’s comments, I dived into the world of 3D printing love toys and bioproofing.

In January, I wrote how the project of building a 3D printer with my boyfriend brought us closer together. Apparently, some readers were expecting more than just an innocent bonding experience. Yes, I’m talking about you, Taconaut!

"And I thought you'd be giving us an instruction on how to print something like this and maybe even make it suitable for Cloud."

Taconaut is right; you can print your own sex toys! And there are ways of making them not only hygienic, but also completely bioproof. And I’ll tell you how.

Less creative alternatives

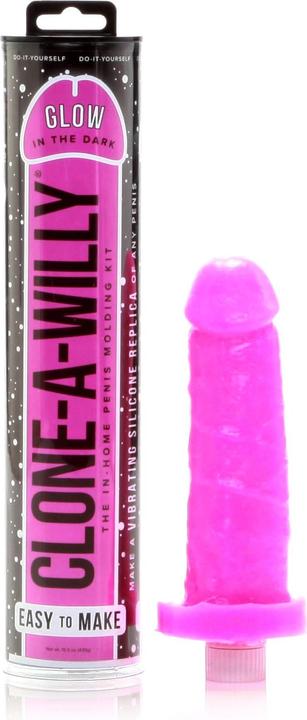

Before getting into the subject too deeply, I’d like to point out that there are also other ways of making a sex toy at home. For example, the Clone A Willy kit comes with everything to make a cast out of your own or favourite joystick. Depending on the kit you choose, you can either fill it with chocolate or platinum cure silicone of different colours – even glow-in-the-dark ones – and an optional vibrator.

With a casting kit, there’s the disadvantage of needing a willing model and few to none options of personalizing it. The best case scenario: what you see is what you get. Worst: you have to repeat the process all over again.

Even though the casting part shouldn’t take more than ten minutes, the silicone takes around 24 hours to dry. That’s a lot of waiting to find out if you succeeded in replicating the original subject.

There’s also a chocolate Clone A Pussy kit of the same brand. It has no other purpose other than to be eaten. And hey, there’s nothing wrong with that! But a bit pointless at this stage as I'm quite sure the chocolate printer has not yet been invented.

If you don’t feel like modelling your own toy, I’ve discovered a few options on Thingiverse.com. But an even more useful page for this purpose is Sexshop3D.com, where you can buy all kinds of models and find great tips regarding materials, processes and safety. Not only that, but you could even sell your own inventions. Which I’ll do.

Safety first

From a dog’s toy to kitchen appliances, the first thing you want to do is bioproof your object. Because the alternative is dire and downright dangerous: You would poison yourself, your partner or your dog. Here, we are dealing with plastic, a potentially toxic material, meeting human flesh. And human flesh is, believe it or not, a lot more sensitive than you might think.

Safety is the number one priority. Simply being able to print a pacifier for your baby, a bracelet for your kid, any kind of short-lived chew toy for your dog or a sex toy would be pretty good, right?

But how to go about it in the wonderful world of 3D printing, you ask? Luckily, the world of DIY offers many options. Needless to say, regardless of the material you choose, make sure your final product is non-porous.

Here are the most popular alternatives you can choose from depending on your project:

- Acrylonitrile Butadiene Styrene (ABS)

- Silicone Coating

- Negative mould

You might already be familiar with ABS. Not only is it the second most popular filament for home 3D printers (after PLA), but it’s also the material used in practically all modern Lego pieces. As it doesn't leak toxic chemicals when used normally on an everyday basis, you could say it is a safe choice for household products. After silicone and rubber, ABS has also been the first choice for the sex toy industry for decades. And they know what they are doing. Here’s something you might not know or don’t want to admit publicly: The sex toy industry is quite advanced, technologically speaking. Their daily business is “Plastic meets flesh” and the industry is well regulated and under tight scrutiny by pretty much everyone.

As I’m still quite new to the 3D printing world, calibration is still a nightmare. When it comes to calibrating the setting for ABS, it gets even worse. So for this project I’ll stick to my good old Polylactic acid (PLA), the most popular option in home 3D printing.

Although PLA is biodegradable, it’s not listed in the Food Compliant Materials table of most –if not all – regulatory agencies. This is how you know if it is safe to interact with your food. And if you don’t want it to get in contact with your food, you don’t want it anywhere near your nether parts.

Honestly, I didn’t find any information against using it for a sex toy, but if there aren’t any on the market that are made out of PLA, there must be a reason for it. But the project I work on in this article is just a prototype and not suitable for personal use, so I’m not really worried about it. However, I would advise against it if you want to go down the route of printing your own sex toy – a make sure you use ABS instead.

In case you had something different in mind or wanted your own model to be similar to Clone A Willy, you can always design and 3D print a negative mould for the silicone. Then, use that negative mould and the Clone A Willy raw materials to get a bioproofed print of your sex toy.

It’s worth emphasizing how important it is to have a perfectly smooth surface. The plastic is delivered in layers, so there will be gaps in even the most perfect of models. No object is ready for use right out of the printer. You need to make sure you don’t accidentally injure yourself during use as well as make sure you don’t poison yourself.

Even with some sanding or a chemical bath to smooth the surface, some tiny holes might persist. These are ideal places for bacteria to hide and thrive, and you don’t want that happening on such a personal device. That’s why I insist on applying several layers of food-grade silicone spray or coat it with silicone rubber.

Fieldwork

When it comes to sex toys, I must admit I don’t know much. To fix that, I spent a whole half an hour in my local sex shop. And let me tell you, I wasn’t aware of all the wonders currently available!

Something that stood out for me were the vibrating patterns, which were the exact same eight speed settings for most vibrators. It’s like that range of sounds you’ll find in most generic plastic guns.

With the rabbit models, the stock vibrating pattern was limited to the small rabbit part, while the head rotates in three different speeds.

There was one toy that stood out from the crowd, and I must admit it felt really nice, at least on my hands. I’m talking about the Stronic line from Fun Factory. Instead of rotating or vibrating, it actually quite vigorously emulated the thrusting movement by itself. Kudos, little toy! The silicone wasn’t particularly soft in comparison to other vibrators, but that movement exceeded what I would expect from any sex toy. I had to share that with you.

I left the shop as I arrived: Empty-handed. But now, I can proudly say I have an idea of what’s currently offered on the market.

Let's get down to business

With all the alternatives that are being sold right now, why limit yourself to making it anatomically correct? There are products out there that promise a world of pleasure with elegant, abstract shapes. It’s worth stressing that these toys are also on the expensive side.

Before working on the 3D model, I had to consider the limitations of my printer: Like not being able to print on thin air or steeper than 45° due to our non-existent cooling fan by the nozzle. Also, materials and the functionality I wanted to achieve played a big part in the design. With all these things in mind, I decided to take the Liv 2 model from Lelo as my main inspiration for this project.

After a long weekend, I created and modelled a system that would house a bullet vibrator. Not only that, but you one where you can activate the bullet with a button I designed on the cap, so no disassembling would be necessary between uses.

After three prints of the upper part – which takes three hours each– I finally had a version I liked. The cap took five tries to get the button working perfectly; luckily, it was just an hour per piece.

Then comes the finishing. With this kind of object, I can’t stress enough how important a non-porous surface is. So I filled the few holes with UV-curing adhesive, a plastic that dries through UV light. It’s ideal for applications that require resistance to thermal cycling under vibration, environmental exposure or biocompatibility.

Once the surface was completely closed, I sanded the pieces, covered them in silicone spray a few times and that was it. But enough talk, just watch:

There's no way on earth I'd film myself sanding that thing.

It was a fun project overall. Honestly, I enjoyed the modelling way more, but having a functional button is very rewarding. I’m not happy with the finish the silicone spray provided. It would take at least ten more layers to achieve a smoother effect.

If I ever do this again properly, I will coat it in the Clone A Willy silicone right out of the printer and get over with it.

Your go

If you want to try this yourself: I used the most basic bullet vibrator I found on Galaxus. For the printer, there is a wide variety of models. You can get mine here. And, as said before, I recommend the platinum cure silicone from Clone a Willy for a professional and safe-to-use finish.

Now you know. You can make your very own sex toy in the comfort of your own home. So let your imagination run wild and start printing! Don’t forget to have a toy cleaner to apply before and after every use. Have fun!

System JO Travel Toy Cleaner

Pjur Woman Toy Cleaner

100 ml

I might be a graphic designer, a Pokémon trainer and tech-savvy but I'm no creative writer. I'm on a non-stop quest against bad design. Since 2014, I call Switzerland my home.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all