Company news

Our carbon footprint: power heroes, heating zeros

by Tobias Billeter

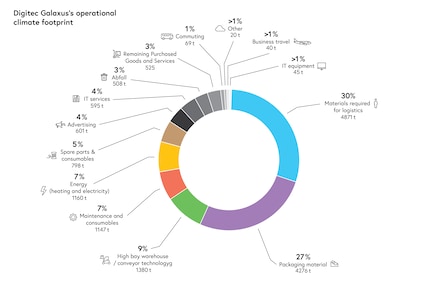

The rapid growth of the last two years is leaving its mark on our in-house climate footprint. Overall, our greenhouse gas emissions have grown, but per shipment they’ve shrunk by 44 per cent. That’s thanks to our increased use of renewable energy, efficiency programmes, and optimised packaging as well as reduced commuting among our employees.

We’ve now measured and analysed our operational climate footprint for the second time, following an initial analysis in 2019 and recently completing a second survey for the 2021 fiscal year. Keep in mind, we’ve collected additional data during the analysis to accurately reflect the change in the parameters of the survey. In so doing, we’ve accounted for additional emissions resulting from growth and we’ve updated some calculation bases of the initial survey.

If we break down our 2019 operational CO2 emissions into major categories and compare the figures with those of 2021, the result is encouraging. Our climate footprint in marketing has shrunk by 80% to 601 tonnes of CO2. Emissions caused by heating and electricity have also fallen. By 23% to be exact. That’s because we’ve switched to renewable energies and become more efficient. Just look at our warehouses, where we use mostly LED lighting.

Employee commuting shows an even more impressive drop in emissions. At 69 metric tonnes, 2021 emission levels were just under one-tenth of those in the initial survey. This miraculous decline is a result of the corona-induced home office boom. Since working from home is here to stay, emissions from employee commuting should tend toward zero in the medium to long term.

Let’s also break down our use of packaging materials. Our material-related emissions increased by 84%; this was primarily due to the fact that the number of parcels we shipped almost tripled within two years (+170%). yet, our two new packaging machines and optimised cardboard boxes have positively impacted our carbon efficiency. We’ve exceeded our target of reducing CO2 emissions from packaging material per product shipped from our own warehouse by at least 3 per cent annually.

If we look at the absolute numbers, our in-house emissions have grown by 40% since 2019. This increase stems from two areas in particular. The additional use of warehouses commissioned between 2019 and 2021 resulted in increased greenhouse gas emissions in the areas of high-bay storage/conveyor technology (+81%) and maintenance and consumables (+227%).

This is because operating the new, automated warehouses requires the use of additional consumables such as Euro pallets and slotted cardboard boxes, which now fall into the category «Materials Required for Logistics». At 4,871 metric tonnes of CO2, this category accounts for around one-third of our total operational footprint. Our remaining Purchased Goods and Services category, which includes all office consumables such as printers, furniture, monitors and notebooks purchased for personal use during the pandemic, is also worth noting.

In any case, our progress has been remarkable. We’ve been able to substantially decrease emissions in areas where we see some of the highest CO2 production: marketing, energy and commuter traffic. And when it comes to packaging, the investments in material efficiency and packaging machinery are also paying off. For 2021, we can definitely say that overall, operational greenhouse gas emissions per delivery have shrunk by 44 per cent compared with 2019. Continuing such progress in the coming year is our next challenge.

Making sure employees and media know what's up at Digitec Galaxus is my job. But without fresh air and a lot of exercise, I basically stop functioning. The great outdoors provides me with the energy I need to stay on the ball. Jazz gives me the tranquility to tame my kids.

Everything you'd usually read on a news portal or in the newspaper can be found here, directly from the source: annual figures, new services, our efforts for greater sustainability, sales trends and so on.

Show all