Background information

Fairphone 3: Review superfluous

by Dominik Bärlocher

If you send your smartphone in for repair, there's a good chance it will end up in Hartmannsdorf. Around half a million smartphones are repaired every year in this small town in Saxony, around 20 minutes by car from Chemnitz.

About 250 people work here in a so-called ESD area of repamo.com and W-Support for which special rules apply to protect against electrostatic discharges. For me as a visitor, this means wearing a lab coat with interwoven metal threads and shoe covers.

After the tour of the workshop, we head to the training room, where new employees are trained and new smartphones are repaired. A workstation including tools and a smartphone is prepared for me. My task: replace the display.

I'm already wearing a lab coat and shoe covers to protect me from electrical discharges. Before I can pick up my smartphone and tools, I have to ground myself with a wristband and a cable. Without these safety measures, there is a risk of discharge. I would then get a "wipe", which is not dangerous for me, but can destroy the circuit board of the smartphone. That wouldn't be so bad for our test objects, but it would be damaging to our customers' devices.

After the preparations are complete, I am handed my smartphone. The Samsung Galaxy S7 was previously placed in a special oven at 70 degrees for a quarter of an hour. This is necessary to soften the adhesive that holds the smartphone together.

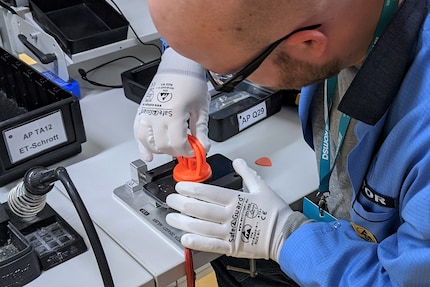

First you need strength. I clamp the S7 in a vice and attach a suction cup to the back. I have to pull on this to lift the back slightly and push a thin "pick" into the opening. By moving it back and forth, I separate the adhesive until I can remove the entire back.

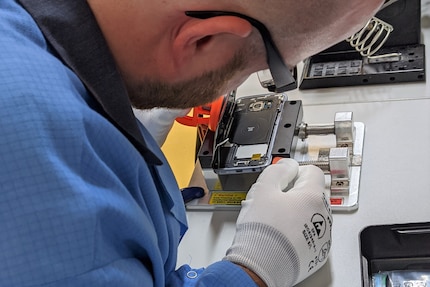

Tool change. I need a screwdriver. Fortunately, a classic Phillips model is enough for Samsung. I have to unscrew a total of twelve screws before I can remove two plastic covers with a plastic spatula. The entire electronics are now exposed. The main circuit board has to come out, but it is still held in place by eleven connectors. I also loosen these with the spatula. Some components, such as the camera or the 3.5 mm socket, are individual parts and don't necessarily need to be removed to change the display.

In the heat of the moment, I want to remove too much and cut a connection to the back button on the front. At that moment, I'm glad I only have a practice device in my hand. In an emergency, however, repamo.com would also have this individual part in stock and could replace it if it breaks during a real repair. The real workshop is divided into areas for the respective manufacturers so that employees have short distances to spare parts. Each person is usually trained to repair several devices. If I were not just a visitor but an employee, the training would have prevented the faux pas.

The 250 people in smartphone repair are part of a total of 1,300 people who work at "Komsa" in Hartmannsdorf. Put simply, the company has been involved in bringing phones - and other electronic items - to retailers in Germany since 1992. The repair workshop is an addition to this and the difference between the two brands can be explained as follows: W-Support primarily takes care of warranty cases under the strict specifications and on behalf of several manufacturers such as Samsung, Huawei or Sony. Repamo.com works under less strict guidelines and can therefore offer cheaper repairs.

I'm slowly realising why I have to remove so many parts of the Galaxy S7 to change the display. The individual components are located at the front and back of the metal frame, in the centre of which there is also a thin metal plate. Despite this separation, the components are connected at several points. And it is precisely these connections that I have to loosen.

Now the smartphone is warmed up again so that I can finally loosen and remove the display with the help of a vice, suction cup and pick. Before installing the new screen, I have to remove the adhesive residue. The construction doesn't have a millimetre of play and the assembly could fail due to such impurities.

There are two challenges: I have to puzzle and put all the pieces back together in the right order. This is made more difficult by the fact that I have to apply the adhesive moulds supplied by Samsung in the specified places. It's more difficult than I thought and I curse the person who came up with the idea of using glue to assemble smartphones.

In the end, I manage to get the display, the circuit board and all the other electronic components in the right positions and to restore the plug connections. However, there's not enough time for the dozen small screws. I was too slow. My tour continues. I can't test whether the Galaxy S7 works with the new display and whether the part is waterproof is also more than questionable.

Lesson of the day: With the right tools and a little practice, a smartphone can be repaired. But I wouldn't try it at home, even if I could somehow get hold of the spare parts and tools. However, the Fairphone 3, which is specially designed for private repairs and is only held together by screws, is a completely different story.

When I was but a young student, I'd sit in my friend's living room with all my classmates and play on his SuperNES. Since then I've had the opportunity to test out all the newest technology for you. I've done reviews at Curved, Computer Bild and Netzwelt, and have now arrived at Galaxus.de.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all

Background information

by Kevin Hofer

Background information

by Stefanie Lechthaler

Background information

by Stefanie Lechthaler