Spice up your relationship with a home-made 3D printer

Sometimes, keeping things interesting with your partner can be a tricky thing to do, particularly when the magic of a new relationship fades. So why not bring back the thrill of something new with a 3D printer? Maybe this is exactly what your relationship needs.

When I met my boyfriend, he told me just how much he liked the concept of 3D printing and the idea of implementing his own solutions and ideas by printing things at home. Being a closet product designer (at least that’s what it says in my bachelor’s degree right after graphic design), I had to deal with my fair share of prototyping and 3D printing back in the day, so I knew better. It’s just that in 3D printing, nothing works right from the start and it requires a lot of effort to have a functional result. But that also applies to relationships. It won’t work without effort and it’s way easier when forces are joined in this endeavour.

Fast forward eight months: we are still together. Everything is great, it’s just obviously not as exciting as it was when everything was still new and fresh... that’s until I signed us up for a workshop to build our own 3D printer. My guy was hesitant at first. He loved the idea of it, but investing two days of non-stop labour was a completely different level. In addition, his legitimate scepticism regarding the actual usefulness of the finished product and worrying about ending up with a mere gadget was a big factor against this workshop. Plus, I must emphasize that neither of us are particularly handy. However, after some research and persuading, I got him on board.

Our schedule:

- Day one: Assembling

- Day two: Wiring, calibrating and PRINTING!

Fiddly bits and meeting the "Borad"

Easy, right? Well, not really. I must admit it was pretty exhausting. All those screws, cables and fiddly parts really start to mess with your head when you’re not a natural. But seeing the excitement on his face during the whole process kept me going.

Our range includes similar printersNow for the model: We found ourselves with all the pieces to assemble a FLSUN Metal Frame Prusa i3 scattered in front of us. You know, one of those RepRap self-replicating 3D printers where you can print the key elements yourself and simply buy the rest of the parts. Luckily, the printer controller had an integrated motherboard, which already came pre-installed with the firmware. So all we had to do to get this baby on its feet was follow the badly translated instructions and put the parts together like a knock-off Chinese Lego set. The manual not only contains grammar ranging from questionable to downright wrong but also typos. We particularly enjoyed “Borad” instead of “Board”.

Basically, a 3D printer is a pretty simple device. There’s a kind of roll of plastic “wire” that’s fed into a heated nozzle where it melts before it’s extruded on a plate, layer by layer, until the layers stack up to form a physical object. You can either design objects yourself or just download ready-to-print designs from various websites created by a very active community.

Although you don’t need to be a rocket scientist to do this, I was happy there was a fully assembled model for reference at hand and some assistance from the workshop leader. After all, it’s a device with electric motors and moving parts that work with millimetre precision – it’s no Billy bookcase! Especially tricky was the fitting of the belts that move the printer bed in the Y-axis and the print head in the X-axis, which – of course – I left my boyfriend to struggle with while I made sure to look busy with the electronics.

First the cables then the printing

After assembling all the hardware, the final step was the wiring between the logic board, the motors of the axes and the printer controller. This part also took some creative interpretation of the instructions but was easier than we first feared. Luckily, we both are a bit obsessed with making things look nice and tidy, so neither of us stopped the other in our excessive endeavours to manage and arrange the wiring, even though it added nothing to the functionality.

Once the printer’s assembled, you might think it’s over, but that’s actually just the beginning. Everybody knows that printers can be moody and uncooperative (like boyfriends sometimes), now add one more dimension to it and you’ll get a real challenge.

Like with any other printer, you have to install the drivers on your computer and also a compatible software to send the files to print, which in our case was Repetier Host – a free programme. My boyfriend installed everything on his Windows 10 laptop and was able to connect to the printer in no time. Meanwhile, I struggled with different drivers, which either didn’t work or instantly crashed my Mac. Speaking of moody and uncooperative, there I was, struggling with the curse Apple inflicted upon me for almost an hour. Finally, we were both able to communicate with the printer, but that was enough for me to leave all the technicalities to my talented better half.

Because this was a joint project, we decided that I would stick to the 3D modelling (which I’ve been doing for years) and he would be in charge of the calibrating and printing. Personally, I think I got the better part of the deal. Ladies, make sure to spend a couple of hours learning 3D design beforehand and you can trick your partner into doing the calibration, which will haunt him for the rest of his life every time he wants to print something. But hey, you are in charge of the digital plane – an equally tedious and time-consuming task (not really, if you know what you’re doing, but just act the part).

There are so many variables to configure in order to make a print reasonably decent that I have given up trying to learn what does what. There are motor steps, filament extrusion rates, temperatures, millimetre-precise levelling… a whole plethora of things to adjust. My guy on the other hand sunk his teeth into manuals, instructions, videos and troubleshooting guides like the fate of the free world depended on it. Fortunately, there are loads of resources for all skill levels available on the Internet. He seems to have more or less figured out everything at this stage and, watching me, has even learned a bit about 3D modelling. I fear the day he’ll be able to sail through the whole ordeal alone; but at the moment, he still calls me to do the complicated parts.

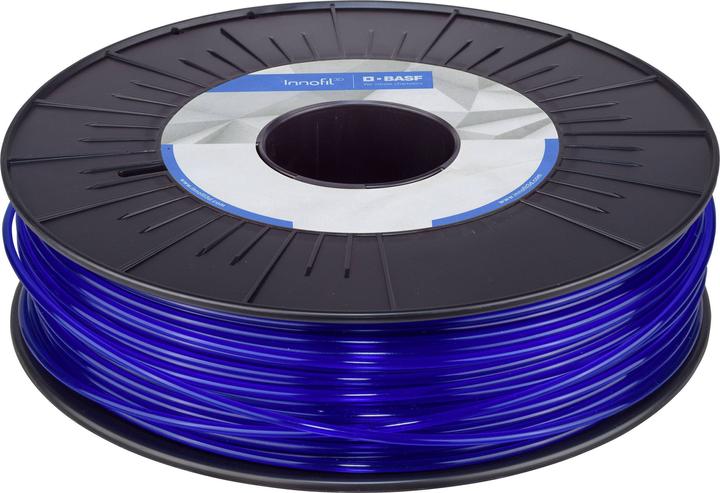

Recently, we (as in: he, and he assures me all of it is very necessary) acquired a bunch of filament in different colours, tapes, adhesive sprays, measurement and crafting tools and started 3D printing like crazy. Lately, one of the most common sights is him checking the printing process and being primarily occupied with calibration prints to check and adjust various settings of the printer. Meanwhile, he has also moved on to print items to improve the printer itself – basically, he’s fixing problems that we wouldn’t have had in the first place.

In the end, we got to do some things that are actually useful; mostly home fixes and little inventions to simplify our lives. For example one of the plastic hangers of his curtains broke, so we just printed a new (and improved) one ourselves. And recently, we developed a cell phone holder with the exact measurements of his iPhone including the case. Now he can hang his phone from an RBS train seat backrest and watch stuff on his commute to work. Now that’s what I call universal solutions! After five prototypes, we had a functional piece completely designed by him, 3D modelled by me and printed by him. This piece represents the essence of what my boyfriend wanted to get out of 3D printing: An individualized solution for an everyday problem – something you can’t buy anywhere.

Overall, it was a very cool project that brought us together even more. He keeps learning more about calibrating the printer, different materials and the whole process and I get to refresh my 3D modelling skills. Teamwork! It is very fun and rewarding to make your own stuff but also somewhat challenging because of the occasional issue. Be aware though, you may also end up in heated discussions about how to tackle the tiniest of issues – especially if his brain is wired like an engineer’s and yours like a designer’s.

Communication, cooperation, patience, trust. These are all qualities that will not only benefit any relationship but are also essential for this project and any printer out there, because they’re tricky beasts. If you can build your own 3D printer and make it work without giving in to the temptation of hitting it with a wrench, you can do the same with your partner without tearing each other apart. So why don’t you try it out? Just make sure to keep that wrench out of reach.

And finally, the fruit of our labour: Our 3D printer printing something for the first time.

You might also like (in German):

I might be a graphic designer, a Pokémon trainer and tech-savvy but I'm no creative writer. I'm on a non-stop quest against bad design. Since 2014, I call Switzerland my home.