Background information

Is PLA really biodegradable?

by Kevin Hofer

Is PLA the same as PLA? I want to know for sure and grab PLA from seven different manufacturers in our shop. In the first test of a multi-part series, I take a look at print quality and handling.

PLA, or colloquially polylactic acid, is the material of choice for hobby 3D printers. It is easy to handle and the quality is good. Around a third of prints worldwide are made from this filament. It is therefore not surprising that numerous suppliers offer it. Some manufacturers add other substances to the material, while others rely on PLA in its pure form. I grabbed seven filaments from different manufacturers and put them through their paces. In this first test of a series, I take a look at the properties, handling and print quality.

PLA is odourless, hardly warps during printing, does not require a heated printing bed and is one of the more environmentally friendly 3D printer materials. It is made from renewable resources such as corn starch, tapioca roots or sugar cane and requires less energy to process compared to conventional petroleum-based plastics.

PLA was discovered in the 1920s by Wallace Carothers, who also invented nylon. However, the commercial use of PLA was too expensive at the time. It was not until 1989 that it was discovered how PLA could be produced cost-effectively from corn.

The thermoplastic polymer is produced by fermenting a carbohydrate source. The natural product is ground to separate the starch from the maize. It is then mixed with acid and milk monomers. The starch is broken down into corn sugar and finally, through glucose fermentation, into L-lactic acid, the basic component of PLA. Although it is a natural product, it is only degradable under certain conditions.

I tested seven readily available PLA from various manufacturers in the shop. Five of them are "standard" PLA without additional substances. They only differ in price. Each filament has a diameter of 1.75 millimetres. You will also find the spool dimensions in the specifications. This tells you whether the filament will fit your printer.

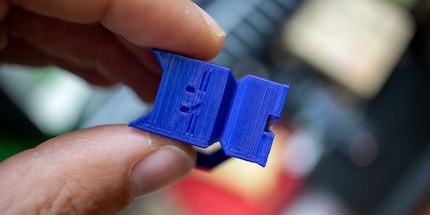

XYZPrinting also manufactures 3D printers in addition to filament. The Junior filament is suitable for the Junior series from XYZprinting or 3D printers with a round spool holder. The filament comes with a built-in NFC chip for recognising the material, but this is only compatible with XYZprinting's Junior printers. The spool has a diameter of around 17 centimetres and is 5.5 centimetres thick. Without the NFC chip, the hub hole diameter measures around 5 centimetres. The junior filament is available from us in seven colours. I got the blue colour. The rolls weigh 600 grams. Calculated per kilo, the spool costs 69 francs.

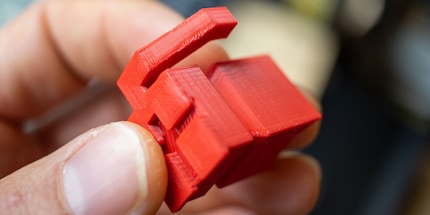

The Best Value Filament is the second cheapest in the comparison test. It is manufactured in Germany. The spool has a diameter of 20 centimetres and is 6.5 centimetres thick. The hub hole measures 53 millimetres in diameter. The spool is now made of cardboard instead of plastic. The material is available in nine colours in our shop. I grabbed red. One roll comes with 1 kilo of filament.

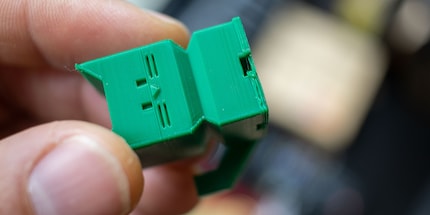

The filament from Purefil is the cheapest filament tested and is made in Switzerland. The spool has a diameter of 20 centimetres and is 6.5 centimetres thick. The hub hole measures 53 millimetres in diameter. The filament is available in 33 colours in our shop. I have the green colour. In addition to the 1-kilo spool, spools of 350, 750 and 2500 grams are also available. [[productlist:10124493]]

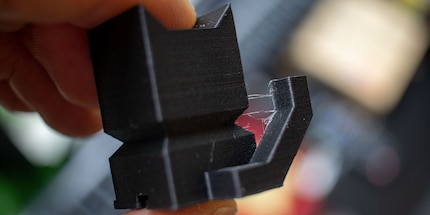

The Makerbot filament is the most expensive pure PLA tested. The American manufacturer also produces 3D printers. A spool has a diameter of around 25 centimetres, but is only around 4 centimetres thick. The hub hole measures around 53 millimetres. The filament is available in 13 versions in our shop. I opted for the transparent one. One spool gives you 900 grams of filament. Calculated per 1 kilo, this results in a price of 67.65.

As the name suggests, Dutch Filaments is manufactured in the Netherlands. The spool has a diameter of 20 centimetres and is 6.5 centimetres thick. The hub hole measures 53 millimetres in diameter. The 1000 gram version of the filament is available in 27 different colours in our shop. I have the orange colour. At 42.80 per kilo, the filament is in the mid-range in terms of price.

The filament from Proto-pasta is PLA, but with 15 per cent chopped carbon fibres added. This makes it stiffer than conventional PLA. It therefore breaks more quickly. On the other hand, it is more heat-resistant and bends less quickly. The filament can wear out your nozzle more quickly due to the carbon. The spool has a diameter of around 20 centimetres and is 5.5 centimetres thick. The hub hole measures 53 millimetres in diameter. There is only this version and it comes with 500 grams of filament.

In addition to PLA, the filament from ColorFabb also contains PHA. Like PLA, PHA (polyhydroxyalkanoate) is a bio-polyester. The mixture makes the filament tougher and less brittle. The spool has a diameter of around 20 centimetres and is about 5.5 centimetres thick. As with most other spools, the side hole also measures 53 millimetres. Unfortunately, the filament is currently no longer available in our shop. One spool weighs 750 grams. At the time of ordering, the kilo cost 62 francs.

I take each filament fresh out of the packaging for testing. I then measure the diameter every ten centimetres over a length of one metre to see whether the diameter is constant.

For this first part of the comparison test, I make three prints each. First, I print a heat tower for each filament to determine the optimum printing temperature. I look at the temperatures at which the print comes out best and calculate an average value from this. I leave the other settings as they are. Here are the most important settings:

Followed by two more test objects: Calicat and Benchy. I print the Calicat with a layer thickness of 0.1 millimetres, the Benchy with 0.2 millimetres. I opt for these two benchmarks because they test everything I need. The Calicat is printed in under an hour and if something is not right, I can make further fine adjustments. The Benchy is the real endurance test.

In terms of handling, all filaments are impressive except one. I produce good to very good prints with six filaments without any problems. Only the PLA with carbon fibres from Proto-pasta presents me with challenges.

It's a real shame that we no longer have this filament on sale. It impressed me across the board. First of all, there is the beautiful, strong and even colour. The diameter of the filament is also uniform: between 1.74 and 1.78 millimetres. Apparently, quality is a top priority during production. The filament is very easy to handle. I use the Heat Tower to calculate an optimum printing temperature of 208° Celsius. This gives me optimum results with both Calicat and Benchy. The layers are applied beautifully evenly, nothing warps and there is no trace of stringing. In short: the prints look great.

Proto-pasta is my enemy in this test. Although it is also very consistent with a diameter of 1.72 to 1.76 millimetres, I don't really want to make any good prints. The filament repeatedly causes a blocked nozzle and therefore unusable prints. The first time with the Heat Tower. At 200° Celsius it's finished and no more filament comes out of the nozzle. I read up on various forums and at Proto-pasta and tried various settings. Clogging occurs again and again, even when I set the temperature to 240° Celsius. Sometimes the nozzle clogs after just a few layers. I have to clean it again and again.

With the recommended settings from Proto-pasta for HTPLA, a similar product to the PLA with carbon fibre, I get a good Calicat at 220° Celsius. Apart from a few threads, the quality convinced me. I assume that the high temperature is responsible for the filaments. The Heat Tower shows that 220° Celsius is probably too much. 215° Celsius or even less would be ideal. Unfortunately, this clogs the nozzle. I also have to increase the layer thickness: to 0.15 instead of 0.1 millimetres.

I try a benchy with the same settings. After about 50 per cent progress, the nozzle clogs again. It's milking the mouse. Desperate, I try one last piece of advice from the Proto-pasta forum: I oil the filament. Yes, it works. I can actually print a Benchy without the nozzle clogging. Unfortunately, it has ugly threads. I reduce the temperature to 210° Celsius and only use a little oil at the beginning, at 30 and 70 per cent printing progress. Once again I succeed with the Benchy. Unfortunately, it still has threads. If I lower the temperature even further, the nozzle clogs up again.

Even apart from the threads, I'm not really happy with the print quality. The first layer is not printed cleanly and the layers are not always applied evenly. However, this may be due to the oil.

The filament from the Dutch manufacturer varies between 1.71 and 1.76 millimetres in diameter. Slightly more than the other two filaments, but still within reason. The optimum printing temperature for me is 208° Celsius. Both Calicat and Benchy look good. No trace of threads. Bridges and details are printed flawlessly. The filament is not entirely convincing when it comes to overhangs.

With the Makerbot filament, I don't have to print quite as hot as with the previous filaments. The Heat Tower shows me 205° Celsius as the optimum printing temperature. The material is uniform with a diameter of 1.73 to 1.77 millimetres. The print quality is also flawless. Only on the tail of Calicat are a few layers not applied completely cleanly. However, the overhangs on Benchy are flawless.

The diameter is the most inconsistent with Purefil filament at 1.71 to 1.79 millimetres. The optimum printing temperature according to Heat Tower is 208° Celsius. The first layers of the Calicat are not optimally printed. There are also slight distortions in the tail and neck. Benchy, on the other hand, is flawless.

The Best Value Filament varies in diameter between 1.72 and 1.77 millimetres. The optimum printing temperature is again 208° Celsius. As with the Purefil filament, I have slight warping in the tail and neck of Calicat. Benchy is flawless again: no threads, clean bridges and surfaces.

The XYZPrinting filament also prints best at 208° Celsius. The diameter is 1.71 to 1.77 millimetres. The Calicat is printed flawlessly. The details are clearly recognisable and the layers are cleanly applied. Benchy also looks good. Only a hint of stringing is visible in the door recesses.

Almost all of the filaments tested produced good results; with a little more fine-tuning, all of them should produce great prints. I only had trouble with the filament from Proto-pasta because the filament always clogged my nozzle. It might be possible to achieve better results with a wider nozzle.

Broken down to the price, this means that even with the Purefill filament, which costs only half as much as the Makerbot filament, good prints can be made. That's why this filament is also the price-performance winner for me. The quality of the prints is on a par with the more expensive filaments.

My personal winner is the ColorFabb filament. The print quality is great and the material feels very good in the hands.

Next time I will test the filaments in an endurance test. I have printed hooks and want to test how much weight I can hang on them. What other tests would you like to see? Write it in the comment column.

From big data to big brother, Cyborgs to Sci-Fi. All aspects of technology and society fascinate me.