Background information

Round two: Radial vs. axial fans for graphics cards

by Kevin Hofer

A compression refrigeration system for PC? That would be like having a freezer in your PC. Yet the cooling specialists at ThermodynamX are building just such a contraption.

In December 2019, I built a water-cooled PC for colleague Simon Balissat. Its unique feature: I used copper pipes instead of plastic ones. A few days later, I received an email from Bernhard Vetsch. He’s a refrigeration technology developer and chief technology officer at ThermodynamX. He knows exactly how to install cooling systems and gave me constructive feedback on my approach. But more importantly: he made a proposal that I, as a PC fan, couldn’t refuse. He wanted to build a compression refrigeration system for CPU.

**Hi Bernhard. Firstly: What even is a compression refrigeration system?**

In a compression refrigeration system, a refrigerant passes through different aggregate states in a closed circuit. The initially gaseous refrigerant is condensed in a compressor. In the process, it gets warmed up and goes into a heat exchanger, where it releases this heat and liquefies in the process. The compressor forces the liquid through a constriction in the refrigeration circuit – the change in pressure causes the refrigerant to cool down considerably. From here it goes on to a second heat exchanger, where the refrigerant absorbs heat and evaporates. It becomes gaseous and can enter the compressor again. The process begins anew. Heat absorption in the second exchanger can be seen as a type of cooling. Active cooling, in this case.

«Active cooling, in this case.»

**That’s the kind of system you want to build into a PC at ThermodynamX. How does this project differ from your everyday work?**

In our day to day, we largely cool things to a certain temperature. Conserving things, or enabling a certain process.

«The more heat is dissipated, the more power can be extracted. We haven’t dealt with that until now.»

**What’s different about this CPU?**

Heat development limits performance and usability. Consequently, heat dissipation allows a processor to work powerfully and reliably. The more heat is dissipated, the more power can be extracted. We haven’t dealt with that until now.

**To what extent do PC water cooling systems factor into your project?**

PC water cooling systems use components similar to compression chillers: a radiator releases that heat into the surrounding air, a thermal coupling to the CPU that absorbs waste heat, and a pump that keeps the cycle going.

**So you can use PC water cooling components?**

Due to the working pressure of refrigerants, the number of viable special water cooling components for PC limited. Take the cooling element for the CPU or radiator. I learned that special water cooling components are allowed a maximum of eight bars for the radiator. For CPU heat sinks, it’s only two bars. That’s why I abandoned the idea. Still, we aren’t limited in our choice of refrigerant.

**Which refrigerants can be considered?**

At first I thought of isobutane. The working pressure of this natural refrigerant is relatively low, but still in the range of five bars. However, its cooling capacity is limited. The pressure for propane is about 2.5 times higher than for isobutane. It’s also more powerful and the components required, such as the compressor, are smaller due to the higher pressures. As a result, this refrigerant lends itself most readily to a compact, high-performance system.

**In what way is a compression refrigeration system more efficient than a classic water cooling system?**

With water cooling, water in the circuit cools the CPU and heats up in the process. The heated water is cooled back to ambient temperature in the radiator. Thus, the CPU’s cooling water cannot be colder than the ambient temperature. This limits the cooling capacity.

**Aren’t there also special cooling systems for PCs, such as Peltier cooling? How does your cooling idea differ from this?**

Peltier does thermoelectric cooling. Its best-known application is probably in thermoelectric coolers. By applying voltage to an element, one side of it becomes colder and the other hotter than its surroundings. The cold side is coupled to the CPU. The heat on the other side must be dissipated, for example by cooling fins and fans. Heat absorption and dissipation over such a small area as a CPU is difficult. Large temperature differences occur, and this quickly degrades the performance of the Peltier element.

**Which means?**

It works well to maintain small temperature differences in the range of 15 degrees Kelvin. However, we want to try to cool a CPU to around 20 degrees Celsius under load, instead of 90°C with common cooling systems. For this, we rely on a refrigerant that can be cooled down to -40 degrees Celsius. A refrigeration circuit is more powerful and efficient in cooling than a Peltier element. On the other hand, the Peltier element is much more compact.

«We require space in the housing, without modifications.»

**I want to cool a Threadripper 3970X on an Asus mainboard in a Define 7 case from Fractal Design. You’ve had the system for a short while. What did you think of it?**

The size surprised me, there’s more space than expected. The largest cooling component will be the compressor. We require space in the housing, without modifications.

**So is there enough space?**

Yes, it should be sufficient. Currently, we’re more concerned about the condensate produced in the CPU area during active cooling with a compression refrigeration system. We have to be careful that it doesn’t get to the electronics. We might have to align the case differently and use liquid rubber Plasti Dip on the motherboard, such as with extreme overclockers. You lubricate the motherboard with it to protect components from the condensate.

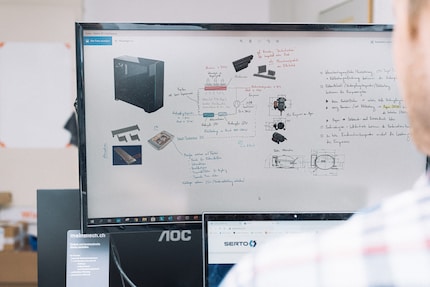

**What are you currently working on?**

We found that we couldn’t use existing PC water cooling components for the most part due to pressure. For the radiator, we decided on one from the refrigeration industry after doing some research, and sized it to just fit inside the case. For the CPU, we split it up: we took the CPU contact plate from an existing water cooling component. We removed the acrylic cover plate and had a new one made from stainless steel. Everything should withstand the high pressures of propane.

«We found that we couldn’t use existing PC water cooling components for the most part due to pressure.»

**Could use of the CPU contact plate also cause problems?**

This is certainly possible. The contact plate is very finely crafted, with many flow channels designed for water as a coolant. A lot of development work has gone into it. Now the question is how well the refrigerant can penetrate the ducts. The refrigerant alone should not be a problem. But with a compression refrigeration system, there’s always some oil as well. We hope this won’t deposit in the ducts and thus reduce the cooling performance. The flow distribution was also optimised for water. Since we’re replacing the acrylic component with stainless steel, we won’t see how it reacts to the refrigerant.

**Where else do you see stumbling blocks?**

For us, this application is unknown territory. We have to approach it carefully. During our initial designs, we always try to create a system that can respond to as many unforeseen events as possible. In this case, this includes using a variable-speed compressor. This way we can make adjustments on the fly.

«For us, this application is unknown territory. We have to approach it carefully.»

**In which sense?**

The radiator is rather small due to the tight space in the case. It may become a bottleneck for heat dissipation. We have to compensate for that with the variable speed compressor. As the name suggests, the speed and thus the cooling capacity can be varied.

**And otherwise?**

Regulation is certainly an issue. We don’t know well enough how the CPU behaves under load. What happens when the CPU and the refrigeration circuit are spinning full, and suddenly the CPU goes idle from one second to the next? All of a sudden it needs less cooling power. How quickly must the refrigeration cycle respond? If it reacts too slowly, there’s a risk of liquid buildup in the compressor.

**What does this mean?**

In the case of liquid buildup, the compressor doesn’t just receive the refrigerant as gas, but also as liquid droplets that cannot be compressed. They can damage the compressor.

**What are our next steps now?**

All refrigeration components have been ordered. As soon as they get here, we’ll build the whole system. Possibly outside the case and away from the PC components for an initial test. If something doesn’t work out, we don’t want to damage them. In addition, we’re currently working on speed control and corresponding measurement techniques.

When the compression refrigeration system is set up and tested for the first time, I’ll be there. If you don’t want to miss that either, click on «Follow author».

From big data to big brother, Cyborgs to Sci-Fi. All aspects of technology and society fascinate me.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all

Background information

by Kevin Hofer

Background information

by Kevin Hofer

Background information

by Kevin Hofer