Background information

Behind the scenes of Switzerland’s most renowned Asian mushroom producer

by Darina Schweizer

Time and patience transform the leaves of the mulberry tree into silk. As President of Swiss Silk, Ueli Ramseier knows this firsthand. Today, he’s inviting us into the world of silk manufacturing in Bern.

«You can never hurry the process of making silk. Not when you’re planting the trees, not when you’re rearing the silkworms and not when you’re unwinding the cocoon thread. If you take it easy, it’ll turn out well,» says farmer and textile engineer Ueli Ramseier, proudly presenting me with a strand of neatly wound silk threads. They’re smooth, shiny and brilliant white – the way I’d imagine the mane of a graceful, mythical creature to look. My first impulse is to touch them, but the silk looks so precious that I hesitate. «Go ahead,» Ueli says. I glide my hand over the threads that will later be woven into organza, damask, taffeta and twill. They feel as exquisite as they look.

Around 15 years ago, Ueli Ramseier teamed up with five farmers to found an association of Swiss silk producers, Swiss Silk. Since then, ten additional silk enthusiasts have joined them to revive the local tradition. Silk production in Switzerland can be traced back to the late Middle Ages. In the mid-19th century, it was actually one of the most important industries in the country, with Zurich’s silk yards among the world’s leading producers. A street in the city’s District 1 area named Seidengasse (literally «Silk Lane») still serves as a reminder of that era.

Almost two centuries later, 120 kilometres to the west, Ueli Ramseier’s organisation is kindling a renaissance of Swiss silk. He says that until last November, an unassuming silk factory in Bolligen, Bern, was the only facility in Europe to be processing silkworm cocoons into silk threads.

The factory doesn’t produce any fabric. Instead, long-standing Swiss companies such as Weisbrod and Minnotex take on the twisting and weaving processes. The fabric that comes from Swiss Silk threads is then used in a wide variety of ways. Furniture store Pfister uses it to make curtains, designer Rafael Kouto turns it into clothes for his sustainable label, and tailors at «Bernische Trachtenvereinigung» use it to make traditional clothing.

When the raw material arrives at the factory, it has a completely different shape. Tightly wound and glued together, the strands form a hard, egg-shaped shell, which takes the mulberry moth caterpillar three days to build. The farmers at Swiss Silk breed the creatures as a sideline in the summer months. These caterpillars exist on a diet purely composed of leaves from the mulberry tree. Although the plant originally comes from China, the home of silk, it also thrives in Switzerland.

Ueli opens one of the dozens of blue bins full of cocoons stored in the factory: «They have to be kept safe because mice go crazy for them.» Working in a team of four, he and his colleagues select the largest, roundest and whitest cocoons from the batch of thousands. Only around a third of the harvest is suitable for the high-quality reeled silk. This comes from the up to two-kilometre-long thread from the middle part of the cocoon.

The second-best cocoons are supplied to the German company Fibrothelium, which specialises in using silk to make protein solutions. These are then used in the manufacture of medical implants and other products. The remaining third of the batch is rejected due to discolouration and impurities. Along with other production residues, it’s then used to make schappe silk, which Swiss Silk is producing this year for the first time. Rather than being made of the long filament extracted from the middle of the cocoon, schappe silk comes from short fibres spun into a fine yarn.

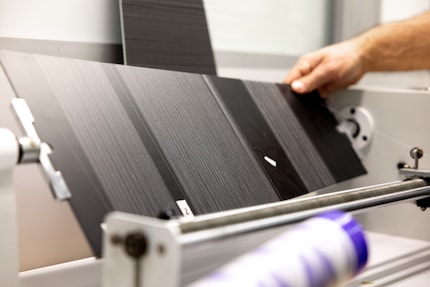

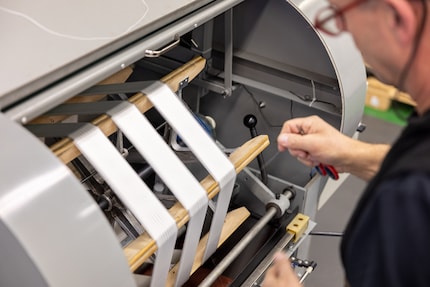

Behind the factory’s gigantic machines, a delicate process takes place. Reeling is a craft that, like rearing silkworms, requires incredibly nimble fingers. With each cocoon, the hard beginning of the thread is loosened with a small broom. A machine then unwinds eight cocoons in parallel and spins them into a single raw silk thread. The machine, however, is unable to thread the strands from the cocoon itself. This part calls for dexterity: up to 2,500 cocoons are unwound in a day – the equivalent of around 350 kilometres of silk thread. The entire process is carried out without using any harmful chemicals. Instead, the cocoons are simply soaked in water.

Ueli takes us into Swiss Silk’s «laboratory», referring to the room with an ironic wink. After all, the people working there aren’t researchers – they’re craftspeople with their hearts set on producing good thread. An ornate set of antique scales catches my eye. «Beautiful, eh?» says the 62-year-old enthusiastically before demonstrating how they test thread strength, i.e. thickness.

The unit of weight is the old French «denier» used for tights, and is measured in grammes per 9,000 metres. Silk thread produced by Swiss Silk comes in at around 20 denier, so can weigh just 20 grammes per nine kilometres.

Another sample is stretched over a black board and scrutinised with the naked eye for irregularities such as small knots. The third step is to test the thread’s cohesion, i.e. robustness, by hand. Although there are specific machines for this, Swiss Silk doesn’t have the money for them at the moment. Ueli takes the thread between his fingers and scrapes it with his fingernail: «If it’s still robust after doing this ten times, the quality’s good. After five times? So-so. Anything below that is poor.» Roughly 20 per cent of threads fall into the latter category. They can only be used for certain fabrics such as Jacquard. In general, Ueli says, the quality of Swiss silk is decent, but there’s still room for improvement in terms of uniformity and cohesion.

«Can you hear that?» Ueli asks. There’s a constant clicking sound in the factory. «It’s a valve opening and closing. It provides a steady supply of warm water during the unravelling process.» He adds that the team built it themselves. It’s a small modification that’s probably responsible for the most striking feature of Swiss silk: its brilliant white colour. To Ueli, however, it’s not just the appearance of Swiss Silk’s product that makes it so special. It’s a tangible, comprehensible thing – an obviously human-made product: «In summer, you can go to the farmers and see how they raise the silkworms and grow the mulberry trees. Our factory’s also open to the public on Saturday mornings during the winter months.»

When Ueli launched the Swiss Silk project, he brought a varied professional background along with him: apprenticeships as both a textile engineer and farmer, a teaching qualification, Bachelor’s degrees in both biochemistry and religious studies and a Master’s degree in ethnology. What he didn’t have was practical experience in silk thread production.

«Back when we launched the project, I went to India and said, ’I’ll buy one of these machines, but I have to learn how it works first,’» says Ueli with a laugh. He adds that he was obviously still an absolute beginner after his two-week crash course. Once back in Switzerland, it was a case of trial and error until he got the hang of it. He and his team picked up a lot of this knowledge themselves: «Sometimes we were on the brink of despair – I had to give a lot of people pep talks. Now, they’re all absolute experts.»

Ueli enjoys reminiscing about these early days. «Some people thought we were crazy – but most people thought our little experiment was cool,» he says. He describes it as a sort of playground, where a lot of volunteer work was involved. With those days over, Swiss Silk’s facing new challenges: «We have to learn to think like an SME. We’re currently in the process of establishing a stable long-term financial strategy and professionalising our organisation.»

Ueli is repeatedly confronted with ethical concerns. Some people find it unconscionable that the cocoons are dried in special ovens with the pupae inside after harvesting. However, if the moths are allowed to hatch, the cocoon is damaged, destroying with it the filament that’s essential for the reeling silk. «I often get critical emails from people – and I understand their point of view,» Ueli says. It’s an issue he gives a great deal of thought: «But as a farmer, I have to come to terms with killing living things. Be it during silk production or while protecting my apples from mice. It’s not easy – and it shouldn’t be.»

Most invertebrates, including insects, are exempt from animal welfare legislation in Switzerland. That’s why Swiss Silk has developed its own standard for «animal-friendly husbandry» of silkworms. This includes banning the use of hormones, limiting transportation to a maximum of six hours and setting out certain husbandry conditions, such as natural light.

For Ueli, respecting and appreciating living creatures also means using as much of the animal as possible. Driven by this conviction, virtually nothing is thrown away in silk production. A balm is made from the gum that holds the cocoon together, while the hard beginning of the silk thread is used to manufacture bars of soap. The dried pupae are sold as hamster food by pet store «Samtpfötli».

«It fascinates me that you really can use everything – even the silkworm droppings. They make excellent compost. In traditional Chinese medicine, they’re dried and served as tea,» explains Ueli, holding a jar of dried caterpillar poop under my nose. It smells like black tea.

Ueli sees working with a fabric as fine and precious as silk as a great privilege. «I’m moved by the beauty of the silk,» he gushes. By beauty, he isn’t just referring to how glossy and delicate the material is. He’s also talking about the sophisticated production process that starts with the mulberry leaf and ends in silk. About the numerous ways in which the cocoons are valuable. The cultural significance and millennia-old history of this precious material – a history that’s continuing with a new chapter written by Ueli and others like him.

Has endless love for shoulder pads, Stratocasters and sashimi, but a limited tolerance for bad impressions of her Eastern Swiss dialect.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all